分手之後,過得更好的兩個人

在網頁專案中常會碰到在介面上需透過資料庫提供的資料來進行呈現,這樣的介面在程式開發時通常會透過兩種方法進行, 以下針對上述的兩種方法進行一些工作方式說明與做法上的分享 。

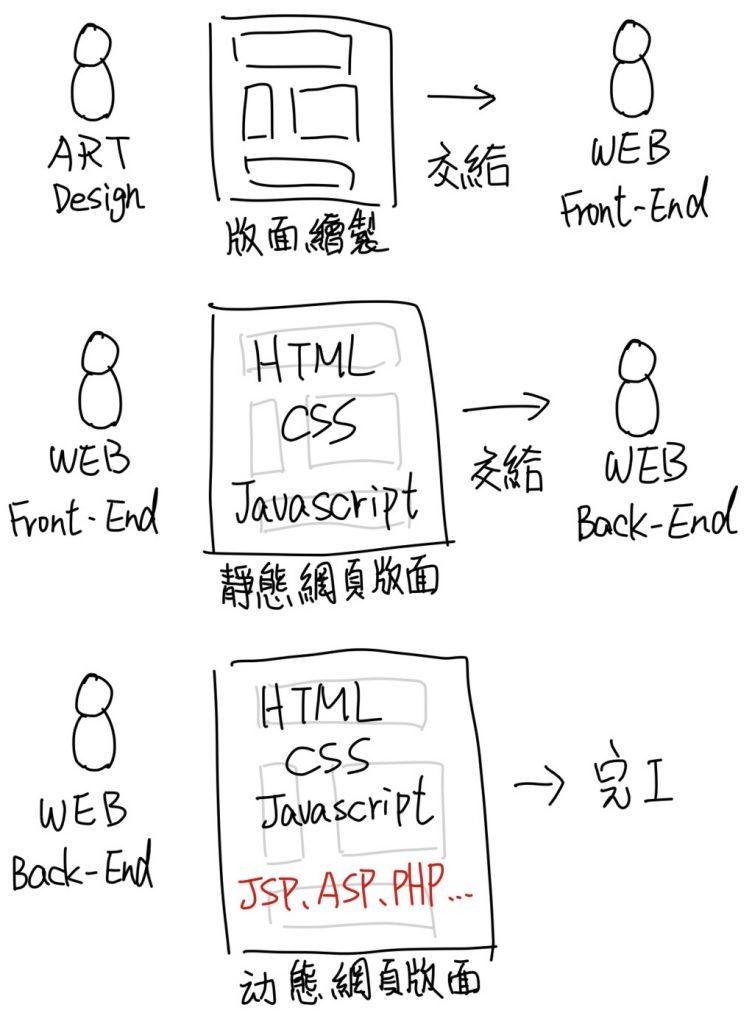

傳統的開發模式

前、後端人員會先針對頁面設計進行可行性的討論,在前端在頁面製作完成後,逐步Release出來給後端工程師,讓後端工程師根據已經製作好的頁面進行施工,他們會在版面中加入後端程式(ASP、PHP、JSP…等),以此方式進行介面設計,最後會在後端工程師處完稿。

上圖的動態網頁版面是指將頁面串接上資料庫(Dynamic),透過資料庫的資料來進行呈現,也就是資料是”活的”,通常前端工程師會在版面中先放入一些假資料,讓後端工程師了解呈現風格,此處的動態不是指動畫,任何在頁面上的互動或動畫,應該是由前端工程師來完成。

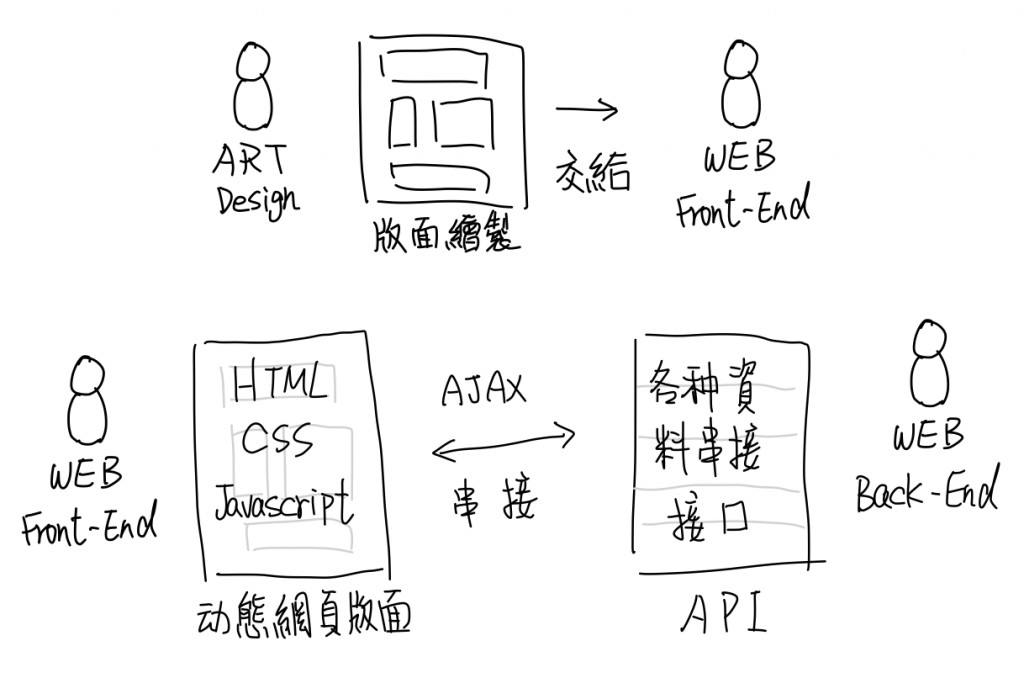

前、後端分離

理想的做法是後端人員幾乎不用了解前端介面想如何呈現,所有API為前端人員依據頁面開需求給後端,例如產品目錄頁需要一隻API可以呈現:

- 商品名稱

- 價格

- 顏色

- 尺寸

- 依據前端傳入的參數來定義

- 一次給幾筆

- 從第幾筆開始給

- 可透過什麼條件進行篩選

以此方式進行介面設計,最後會在前端開發者處完稿。

前、後端分手後的好處

前、後端合併是傳統的合作模式,當時前端沒有好的方法可以呼叫後端API,所以所有的串接都必須由後端工程師進行協助,而自從前端程式可以透過AJAX的方式呼叫後端程式後,前、後端分離的做法就被廣為應用,他也帶來了以下的優點:

1. 權責區分明確

前、後端分離讓人員可以各自負責自己擅長的部份,前端工程師不會需要碰到伺服器端的程式,後端工程師也不會碰到前端的動畫或版面程式,能將權責清楚的區分出來,不會到時候發生網頁跑版、動畫出問題,但不清楚到底是誰動到了不該動的東西。

所以前、後端分離也就是權責上也更能夠釐清,別小看這個部分,因為這不僅僅讓雙方人員在專案開發上目標更為明確,也能夠讓專案管理變得更輕鬆。

2. 跨平台的API應用

專案中的應用平台有時不僅僅是Web,若有其他平台也有後端的需求,之前開發出來的API規格依然可以生效,就算有修改,也能依照相同的精神調整,對於後端工程師來說工作可以更單純一些。

3. 平行的開工時間

在看到ART Design所設計出來的頁面後,雙方可以迅速討論並且同時開工,不像傳統的專案,後端工程師需要等前端頁面完成後才可以施作,更能夠提升專案上的製作行程。

vibration analysis

The Importance of Oscillation Control Equipment in Industrial Equipment

Within industrial environments, equipment and turning machinery serve as the foundation of operations. Yet, one of the commonly widespread concerns that might hinder the functionality along with durability is vibrations. Resonance may bring about a variety of complications, such as reduced exactness along with efficiency to elevated erosion, finally bringing about costly interruptions along with repairs. This is the point where vibration regulation systems proves to be essential.

Why Vibration Control remains Important

Resonance inside machinery might bring about various negative outcomes:

Minimized Operational Effectiveness: Excess vibrations can lead to discrepancies and imbalance, minimizing overall effectiveness with the machinery. Such a scenario might bring about slower production schedules and greater power consumption.

Elevated Erosion: Constant vibration increases overall damage to machinery parts, leading to increased servicing and a possibility of unexpected unexpected breakdowns. This not only increases operational costs as well as limits the lifetime for the devices.

Safety Dangers: Unchecked oscillation could introduce major security risks to both the machines as well as the workers. In severe cases, severe cases, it could result in catastrophic equipment failure, jeopardizing operators and leading to widespread destruction in the facility.

Exactness and Quality Issues: For sectors that depend on precise production, such as production or aerospace, resonance could cause flaws with production, leading to defects and increased waste.

Reasonably Priced Approaches for Vibration Control

Investing in vibration management systems is not only a necessity and also a sound investment for any company dependent on mechanical systems. We offer modern vibration control systems work to built to mitigate vibrations within any machine or spinning equipment, guaranteeing uninterrupted as well as effective performance.

Something that sets our apparatus apart remains its economic value. We know the value of cost-effectiveness in today’s competitive market, which is why we provide premium vibration control solutions at rates that won’t break the bank.

Opting for our equipment, you are not just securing your machines and enhancing its operational effectiveness but also investing into the sustained achievement in your organization.

Conclusion

Resonance mitigation is a necessary factor of maintaining the operational performance, safety, along with lifespan of your machines. Through our affordable oscillation control systems, you can ensure that your operations function efficiently, all manufactured items are of high quality, along with your employees stay safe. Do not let vibration undermine your business—invest in the correct apparatus now.

vibration analysis

The Importance of Resonance Regulation Systems in Mechanical Systems

Within industrial settings, machines and turning devices serve as the support of output. However, an of the highly common challenges which can obstruct its efficiency and lifetime exists as oscillation. Resonance may bring about a series of issues, ranging from lowered accuracy along with efficiency leading to elevated damage, in the end leading to costly delays and fixes. This is the point where vibration regulation tools becomes essential.

Why Vibration Management is Necessary

Vibration inside equipment can lead to numerous negative effects:

Minimized Operational Effectiveness: Excess oscillation could cause discrepancies and imbalance, reducing the productivity with such equipment. Such may bring about slower production times along with greater electricity usage.

Elevated Wear and Tear: Constant vibrations increases the damage of mechanical parts, bringing about more frequent repairs as well as the chance of unexpected unexpected failures. This does not just raises maintenance expenses and limits the lifetime of the equipment.

Safety Risks: Unchecked oscillation could pose considerable safety risks for both the equipment as well as the personnel. In severe cases, extreme situations, this could bring about disastrous equipment breakdown, endangering operators and resulting in extensive destruction in the facility.

Precision along with Manufacturing Quality Problems: For fields where demand high accuracy, such as production as well as aerospace, resonance may bring about flaws with manufacturing, producing defective products as well as increased waste.

Economical Approaches for Vibration Management

Investing in vibration management apparatus is not just a necessity and a sound investment for any industry dependent on equipment. Our cutting-edge vibration mitigation tools are designed to reduce resonance within all machinery or rotational systems, ensuring smooth and effective performance.

What distinguishes these systems apart is its reasonable pricing. We understand the significance of cost-effectiveness within the modern competitive marketplace, which is why our offerings include premium vibration control solutions at prices that are reasonable.

Through selecting our systems, you’re not only securing your machinery as well as boosting its operational effectiveness but also investing in the long-term success of your business.

Final Thoughts

Vibration management remains a vital aspect in preserving the operational performance, protection, along with longevity of your machinery. Using our affordable vibration control equipment, you can ensure that your operations operate seamlessly, your products are of high quality, and your employees remain safe. Never permit resonance compromise your operations—invest in the right equipment today.

мастер по телевизорам на дом москва

You made some decent points there. I regarded on the internet for the problem and found most people will go along with together with your website.

Review my homepage … Daycares By Category

ремонт телевизора на дому в москве

Здравствуйте!

Мы изготавливаем дипломы любой профессии по выгодным тарифам.

lms.jolt.io/blog/index.php?entryid=9298

The Cruciality of Vibration Mitigation Systems in Machinery

Across industrial environments, machinery and rotating systems are the backbone of output. However, one of the commonly common problems that can affect its functionality and lifetime remains resonance. Vibrations can bring about a array of challenges, from reduced exactness and productivity resulting in greater wear and tear, eventually resulting in pricey downtime along with fixes. Such a situation is where resonance control equipment becomes essential.

Why Vibration Management proves Necessary

Oscillation in machinery may bring about various detrimental impacts:

Lowered Production Efficiency: Exaggerated oscillation could result in imbalances along with imbalance, reducing the productivity of the systems. This can result in slower manufacturing speed and greater energy use.

Heightened Deterioration: Continuous resonance increases total wear and tear to mechanical parts, bringing about additional servicing and an chance for unanticipated unexpected failures. This doesn’t merely increases operating costs and shortens the longevity for the devices.

Safety Risks: Unchecked vibrations can present major safety concerns for the machinery and the equipment and the personnel. In severe cases, extreme situations, such vibrations can result in disastrous system collapse, threatening operators along with resulting in considerable devastation in the site.

Exactness and Quality Challenges: For fields that depend on precise production, for example manufacturing as well as aerospace, resonance might result in flaws during the production process, leading to defective products along with more waste.

Reasonably Priced Options to Vibration Regulation

Investing in the oscillation control systems remains not just essential but a wise choice for any business any business that relies on machines. We offer state-of-the-art vibration management systems are designed to built to reduce resonance from any machine as well as spinning equipment, ensuring smooth and effective performance.

What sets these apparatus from others is its economic value. It is recognized that the necessity of affordability in the modern competitive marketplace, which is why we have premium vibration management solutions at pricing that remain budget-friendly.

Through selecting our equipment, you’re not only protecting your machines and increasing its operational effectiveness you’re also investing towards the long-term success of your company.

Final Thoughts

Vibration management remains an essential element in ensuring the operational performance, protection, and durability of your machinery. Through our economical vibration control equipment, it is possible to make sure your processes function efficiently, your products maintain top quality, and all personnel are protected. Don’t let vibrations undermine your machinery—make an investment in the appropriate systems immediately.

Если вы искали где отремонтировать сломаную технику, обратите внимание – тех профи

The Importance of Vibrations Mitigation Tools in Industrial Equipment

Across industrial settings, equipment and spinning machinery are the support of operations. Yet, a of the commonly common problems that might hinder the efficiency and durability is oscillation. Vibrations could cause a variety of issues, such as minimized exactness as well as efficiency to greater damage, in the end leading to expensive interruptions along with maintenance. This is where vibration management systems becomes necessary.

Why Vibration Management proves Critical

Oscillation in machines can lead to several harmful impacts:

Decreased Functional Efficiency: Excessive vibration may bring about imbalances along with unbalance, lowering the productivity of the devices. Such may cause slower production schedules and increased energy consumption.

Heightened Damage: Ongoing oscillation increases the erosion to machine components, bringing about increased servicing and the risk of unexpected unexpected failures. Such a scenario not only increases production expenses as well as decreases the lifespan of the devices.

Safety Concerns: Unmanaged resonance might introduce substantial dangers to the machinery and the machines as well as the workers. In, severe cases, this might cause cataclysmic machinery failure, threatening workers and causing considerable devastation in the facility.

Precision as well as Production Quality Challenges: For sectors which rely on exact measurements, including industrial sectors or aerospace, vibration might cause errors with the manufacturing process, resulting in flawed products and greater waste.

Affordable Alternatives for Vibration Management

Investing in the oscillation control systems remains not just necessary and a smart decision for any company involved with mechanical systems. The offered state-of-the-art vibration mitigation tools work to intended to reduce resonance within various machinery as well as spinning equipment, guaranteeing uninterrupted along with effective performance.

What sets such equipment above the rest is its economic value. We understand the importance of cost-effectiveness within the current market, which is why our offerings include top-tier vibration management solutions at costs that are reasonable.

By selecting our equipment, you’re not only securing your machines and increasing its efficiency as well as investing towards the long-term achievement in your organization.

Final Thoughts

Resonance mitigation remains a critical factor of maintaining the efficiency, safety, along with lifespan of your machinery. With these reasonably priced vibration control equipment, it is possible to make sure your operations function efficiently, your products remain top-tier, and your employees stay secure. Do not permit resonance compromise your company—put money in the correct apparatus today.

ремонт телевизоров в москве

vibration analysis

The Importance of Vibrations Regulation Equipment in Industrial Equipment

In industrial contexts, machines along with spinning systems constitute the backbone of output. Nonetheless, a of the highly prevalent challenges which may obstruct their performance along with lifespan exists as resonance. Vibration may result in a variety of complications, ranging from minimized precision and effectiveness leading to elevated wear and tear, ultimately resulting in expensive downtime along with restoration. This scenario is why vibration control apparatus is vital.

The Reason Vibrations Mitigation proves Crucial

Oscillation inside machines can lead to several detrimental effects:

Minimized Operational Performance: Exaggerated resonance might lead to misalignments and unbalance, decreasing the productivity of the systems. Such a scenario can lead to slower manufacturing speed as well as greater energy use.

Heightened Erosion: Continuous vibrations increases total damage in mechanical parts, bringing about additional upkeep as well as the possibility for unanticipated unforeseen malfunctions. This does not just increases production expenses and shortens the longevity for the machinery.

Security Dangers: Excessive resonance can bring significant security risks to both the machinery as well as the workers. In, serious conditions, such vibrations can result in devastating system collapse, endangering workers as well as bringing about widespread destruction to the environment.

Exactness as well as Quality Problems: For businesses where demand high precision, such as industrial sectors and aerospace, vibration could result in flaws in the manufacturing process, leading to flawed products and increased waste.

Cost-effective Solutions for Vibration Regulation

Investing in resonance control equipment is not just a necessity but a wise choice for any industry dependent on equipment. Our state-of-the-art vibration control systems are engineered to reduce oscillation from any equipment or rotational systems, ensuring uninterrupted and effective performance.

What differentiates our tools from others is its its reasonable pricing. We know the significance of cost-effectiveness inside the modern competitive marketplace, which is why we have high-quality vibration control solutions at pricing that are affordable.

By selecting our systems, you’re not only preserving your mechanical systems along with increasing its productivity but also putting resources towards the long-term achievement of your company.

Conclusion

Resonance mitigation is a critical factor in ensuring the operational performance, protection, and longevity of your industrial equipment. Through our cost-effective oscillation control systems, you can ensure that your operations function efficiently, all goods maintain top quality, and your employees remain safe. Do not permit vibration jeopardize your operations—make an investment in the proper tools immediately.

The Importance of Oscillation Regulation Apparatus in Mechanical Systems

In industrial contexts, machines as well as spinning systems serve as the backbone of operations. However, an of the most widespread challenges that might hinder the operation and lifespan remains oscillation. Vibrations could lead to a range of challenges, from minimized accuracy as well as productivity to heightened erosion, finally bringing about costly downtime along with maintenance. This scenario is where vibration control tools proves to be critical.

Why Oscillation Control proves Important

Oscillation inside equipment can lead to multiple detrimental impacts:

Decreased Production Performance: Excessive oscillation may bring about discrepancies and instability, minimizing overall effectiveness of the systems. Such can result in slower production times as well as greater energy use.

Greater Deterioration: Persistent oscillation increases total deterioration in machine components, causing additional maintenance and an risk of unexpected unexpected issues. This not only increases operating costs but also reduces the lifespan of the devices.

Security Concerns: Excessive oscillation might pose considerable dangers to both the machinery as well as the workers. In extreme situations, severe cases, it may bring about catastrophic equipment breakdown, endangering personnel and causing considerable damage across the site.

Precision and Production Quality Concerns: In fields that rely on high accuracy, including industrial sectors or space industry, vibration could result in inaccuracies in the production process, resulting in defective products as well as more waste.

Affordable Approaches for Vibration Regulation

Putting money in resonance control tools proves not only necessary but a sound investment for any company that uses machinery. We offer advanced vibration mitigation tools are engineered to mitigate vibrations from all equipment and rotating machinery, providing smooth as well as efficient operations.

What distinguishes our systems from others is its its reasonable pricing. It is recognized that the significance of affordability in the current market, which is why we provide high-quality vibration management solutions at pricing that are affordable.

By selecting these tools, you aren’t simply protecting your equipment along with increasing its productivity as well as investing in the enduring success of your company.

Final Thoughts

Vibration management proves to be a vital element in preserving the operational performance, protection, along with lifespan of your machines. With these reasonably priced vibration management tools, it is possible to make sure your operations run smoothly, all manufactured items maintain high quality, as well as your workers stay secure. Do not let vibrations undermine your business—put money in the appropriate systems today.

Если вы искали где отремонтировать сломаную технику, обратите внимание – профи тех сервис челябинск

vibration analysis

The Cruciality of Vibrations Management Equipment in Industrial Equipment

In industrial settings, machinery and rotating devices serve as the support of operations. However, an of the most prevalent challenges which may affect the efficiency and lifespan remains oscillation. Vibrations might cause a range of issues, from decreased accuracy as well as effectiveness resulting in heightened deterioration, eventually resulting in expensive delays and repairs. This is the point where vibration management tools becomes critical.

The Reason Vibrations Mitigation is Necessary

Oscillation in equipment may result in several harmful effects:

Minimized Functional Efficiency: Excess vibration could result in misalignments along with imbalance, reducing total efficiency of the equipment. This can cause reduced manufacturing speed as well as greater power consumption.

Greater Damage: Continuous oscillation hastens the wear and tear in machinery parts, bringing about additional upkeep and an risk for unanticipated unforeseen malfunctions. Such a situation not only raises operational costs but also reduces the lifespan for your systems.

Protection Concerns: Unchecked vibrations could introduce considerable security risks to the machinery and the machinery and the workers. In, severe cases, this could lead to devastating system collapse, threatening workers as well as bringing about widespread devastation across the premises.

Precision as well as Production Quality Challenges: In fields that depend on high accuracy, such as industrial sectors as well as aerospace, vibration can cause inaccuracies in manufacturing, producing defective products and increased waste.

Reasonably Priced Options for Vibration Management

Investing in vibration management equipment is not merely essential but a smart decision for any company involved with mechanical systems. Our modern vibration mitigation tools are designed to eliminate oscillation in any machinery and rotating equipment, guaranteeing smooth along with productive processes.

One thing that sets these apparatus apart remains its economic value. We know the importance of cost-effectiveness inside today’s competitive market, thus we provide premium oscillation control tools at rates that are affordable.

Opting for these tools, you are not just safeguarding your machines and increasing its performance as well as putting resources in the long-term performance of your operations.

Conclusion

Vibration control remains a necessary factor of maintaining the efficiency, safety, along with lifetime of your machinery. Using our cost-effective vibration management tools, one can make sure your operations run smoothly, your products maintain high quality, along with all personnel remain safe. Do not let vibrations undermine your operations—put money in the right equipment today.

ile kosztuje prawo jazdy

Youre so cool! I dont suppose Ive read anything like this before. So nice to search out any individual with some original thoughts on this subject. realy thank you for starting this up. this website is one thing that’s wanted on the web, somebody with a bit of originality. useful job for bringing something new to the internet!

The Value of Resonance Control Systems in Machinery

Across manufacturing sites, machines and rotating systems constitute the support of operations. However, an of the most prevalent challenges that can hinder the functionality and durability is oscillation. Vibrations could lead to an array of problems, including lowered accuracy along with effectiveness resulting in heightened deterioration, ultimately leading to expensive downtime and restoration. This scenario is where vibration control systems becomes critical.

Why Oscillation Control remains Crucial

Vibration in industrial equipment can lead to various adverse outcomes:

Lowered Functional Productivity: Excessive oscillation could result in imbalances and imbalance, reducing the effectiveness in the systems. This might cause slower production times and elevated energy use.

Increased Damage: Constant vibration accelerates overall wear and tear to mechanical parts, causing more regular upkeep along with an possibility for unanticipated unexpected breakdowns. This doesn’t merely heightens operating costs and limits the durability of the machinery.

Protection Hazards: Unmanaged vibrations can bring considerable safety concerns to both the machines as well as the personnel. In, extreme situations, such vibrations can result in devastating system collapse, endangering personnel along with causing widespread devastation to the environment.

Accuracy and Manufacturing Quality Concerns: For fields that demand precise production, including production as well as aerospace, vibrations might cause inaccuracies in the production process, causing defects as well as more waste.

Affordable Approaches for Vibration Regulation

Putting money in the resonance control tools remains not only a necessity but a prudent choice for any organization that relies on equipment. The offered cutting-edge vibration mitigation tools are engineered to reduce resonance within any mechanical systems or rotational systems, providing seamless as well as efficient operations.

Something that distinguishes such systems above the rest remains its cost-effectiveness. It is recognized that the necessity of cost-effectiveness within today’s competitive market, thus our offerings include high-quality vibration control solutions at pricing that remain budget-friendly.

Through selecting these tools, you’re not only safeguarding your machinery along with improving its efficiency but also putting investment into the enduring achievement of your operations.

In Conclusion

Resonance mitigation is a vital factor of maintaining the operational performance, safety, along with longevity of your industrial equipment. Through our affordable resonance mitigation apparatus, it is possible to make sure your operations function efficiently, all goods maintain high quality, and your workers stay safe. Don’t permit vibration affect your operations—invest in the appropriate systems today.

Если вы искали где отремонтировать сломаную технику, обратите внимание – ремонт техники в барнауле

vibration analysis

The Value of Resonance Management Apparatus in Machines

Within manufacturing settings, devices as well as rotating machinery serve as the foundation of operations. However, a of the highly frequent problems that could affect their efficiency along with lifespan remains oscillation. Oscillation may result in a range of challenges, ranging from minimized exactness and performance to increased damage, finally resulting in expensive downtime and fixes. This is when resonance control systems becomes vital.

The Reason Vibration Control is Important

Vibration within machines might cause numerous adverse outcomes:

Decreased Production Productivity: Excessive vibrations might result in imbalances as well as distortion, decreasing total effectiveness of such systems. Such a scenario can result in slower production times and greater power consumption.

Greater Deterioration: Persistent oscillation hastens the wear and tear to machinery parts, resulting in additional upkeep along with a potential of unforeseen malfunctions. This not only elevates operating costs as well as decreases the lifetime in your equipment.

Safety Risks: Excessive vibrations may bring significant dangers to both the equipment and the operators. In extreme situations, serious conditions, such vibrations might lead to catastrophic equipment failure, endangering personnel along with bringing about widespread destruction to the premises.

Precision as well as Quality Problems: Within businesses that depend on high accuracy, including production or aerospace, vibration may cause discrepancies in the production process, leading to flawed products along with increased waste.

Affordable Options for Vibration Regulation

Investing in vibration management equipment is not merely essential and a sound investment for any industry involved with machinery. Our cutting-edge vibration mitigation tools are engineered to mitigate oscillation within any mechanical systems and rotating machinery, ensuring seamless and effective performance.

Something that differentiates our tools apart remains its cost-effectiveness. We understand the significance of cost-effectiveness in the current market, which is why we provide high-quality vibration management solutions at rates that are affordable.

Through selecting our offerings, you aren’t simply securing your mechanical systems and increasing its performance but also putting investment in the long-term success of your company.

Final Thoughts

Oscillation control proves to be a vital aspect of maintaining the effectiveness, safety, along with lifetime of your industrial equipment. With our affordable resonance mitigation apparatus, it is possible to make sure your operations run smoothly, all goods are of high quality, and your workers remain safe. Don’t let resonance jeopardize your company—put money in the proper tools now.

prawo jazdy kat t

The Importance of Oscillation Management Systems in Machinery

Within industrial contexts, devices along with rotational devices are the support of manufacturing. Yet, one of the most frequent challenges that can obstruct the performance as well as longevity exists as vibrations. Vibration can cause a variety of challenges, ranging from reduced precision and effectiveness to elevated damage, eventually bringing about high-cost interruptions and fixes. This scenario is where vibration management equipment becomes vital.

Why Oscillation Control is Important

Resonance within machinery might lead to multiple adverse consequences:

Lowered Production Productivity: Excessive resonance could cause discrepancies and distortion, minimizing the productivity with the systems. Such a scenario may bring about slower production times and increased energy consumption.

Heightened Erosion: Persistent oscillation increases the erosion of equipment components, resulting in additional maintenance and a chance for unanticipated unexpected issues. Such a scenario not only raises production expenses as well as shortens the lifetime in the systems.

Protection Concerns: Excessive vibration might bring substantial security risks to both the machinery and the operators. In, extreme situations, these can lead to disastrous equipment breakdown, threatening employees and causing widespread destruction to the facility.

Precision and Manufacturing Quality Challenges: In businesses that rely on exact measurements, including industrial sectors as well as aviation, vibrations could bring about inaccuracies with the manufacturing process, resulting in defective products and increased waste.

Economical Options for Oscillation Control

Investing in vibration control equipment remains not only necessary and also a sound investment for any company involved with equipment. Our advanced vibration mitigation tools are engineered to mitigate oscillation from any machine as well as rotating equipment, ensuring seamless and effective performance.

What sets our systems apart remains its cost-effectiveness. We know the value of affordability in the modern competitive marketplace, which is why our offerings include top-tier vibration management solutions at prices that remain budget-friendly.

Opting for our equipment, you are not just safeguarding your equipment and enhancing its productivity but also putting resources towards the long-term achievement of your business.

Conclusion

Oscillation control is a vital component of maintaining the efficiency, safety, and durability of your machinery. Through our affordable oscillation control systems, you can be certain your operations operate seamlessly, your products maintain top quality, as well as your workers stay secure. Do not permit vibration undermine your operations—make an investment in the right equipment immediately.

сколько стоит ремонт телевизора плазма

мастер телевизора

ремонт телевизоров в москве адреса

ремонт телевизоров москва выезд

ремонт телевизора

vibration analysis

The Value of Resonance Mitigation Tools in Machinery

Inside production contexts, machinery and turning equipment serve as the support of operations. However, one of the most prevalent problems that could obstruct the performance as well as lifespan remains resonance. Oscillation might lead to a array of challenges, from decreased precision along with efficiency to greater wear and tear, in the end resulting in pricey downtime as well as fixes. This scenario is why resonance control systems becomes necessary.

The Reason Vibration Management proves Necessary

Vibration within machinery can cause multiple harmful effects:

Lowered Operational Efficiency: Exaggerated oscillation may lead to imbalances as well as instability, minimizing the effectiveness in such machinery. This might cause delayed manufacturing speed as well as increased energy consumption.

Greater Deterioration: Constant vibration accelerates the deterioration of machinery parts, resulting in increased upkeep along with an potential for unexpected breakdowns. Such a scenario does not just raises operating costs but also reduces the lifetime for the machinery.

Security Dangers: Excessive oscillation could pose considerable safety concerns for the machinery and the machines along with the personnel. In extreme situations, severe cases, such vibrations may lead to disastrous equipment breakdown, jeopardizing personnel and causing widespread devastation to the premises.

Accuracy and Quality Problems: For fields that depend on high precision, including manufacturing or space industry, oscillations can cause inaccuracies during the production process, resulting in defective products and more waste.

Affordable Options towards Oscillation Control

Investing into vibration control systems proves not just a necessity but a sound investment for any organization involved with equipment. Our advanced vibration mitigation tools are designed to designed to eliminate oscillation within all machinery or rotating equipment, providing smooth and productive processes.

What sets our systems above the rest is its its economic value. We understand the necessity of affordability inside today’s competitive market, which is why our offerings include premium vibration control solutions at prices that remain budget-friendly.

Through selecting our offerings, you’re not only protecting your equipment and increasing its efficiency as well as investing into the long-term success of your company.

Conclusion

Resonance mitigation is a necessary aspect of maintaining the efficiency, safety, along with longevity of your machinery. With our economical resonance mitigation apparatus, it is possible to ensure your processes operate seamlessly, all goods are of high quality, as well as your workers stay secure. Don’t let oscillation affect your machinery—invest in the appropriate systems now.

ремонт телевизоров в москве недорого

телемастер на дом москва