利用Box2D+WCK賦予Flash物理特性 各種連接器

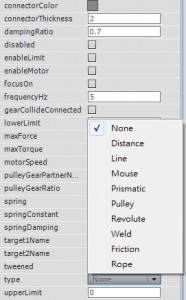

馬老師在前面的文章中已經示範過基本的Box2D+WCK應用以及連接器的製作,這篇文章就來示範在這個模組中所有可以製作的連接器,連接器共有以下八種:

這邊就分別針對這八種連接器做一些介紹和範例。

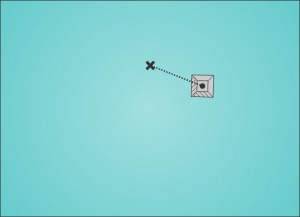

Distance:距離連接器,跟連接的目標保持一定的距離,被連結物件依然可以旋轉。

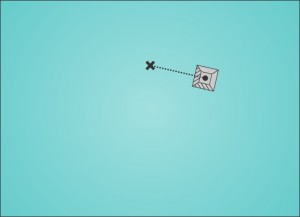

Line:線性連接器,跟連接的目標保持一定的距離,被連結物件無法旋轉。

Mouse:位置連接器,即使被移動依然會回到連接器原始座標。

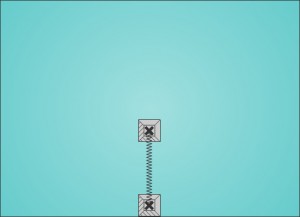

Prismatic:彈性連接器,可以更改不同的彈力數值。

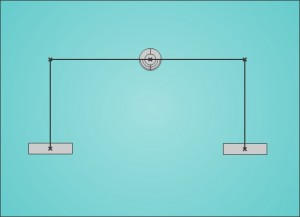

Pulley:滑輪連接器,一邊施加力道另外一邊就會連動。

Revolute:轉動連接器,固定元件中心點。

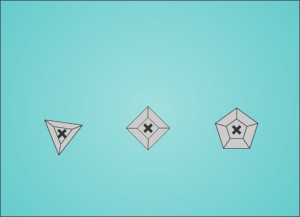

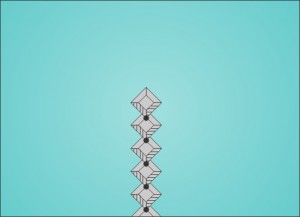

Weld:焊接連接器,將不同的形狀焊接在一起。

Friction:摩擦連接器,讓物體產生磨擦力。

Rope:繩索連接器,用連接線連接物體。

範例檔下載,上述的連結器範例,大家要注意我在連接器上面的組件設定,另外範例檔為CS5格式,下載後要重新設定來源路徑和元件庫路徑喔!(詳見第一篇Box2D+WCK)希望這個範例對大家有所幫助,如果還有疑問,也可以在這邊回應唷~

Saved as a favorite, I love your website.

ремонт шторки затвора фотоаппарата

Upgrade your wardrobe with elegant pieces from pistola jeans sale.

Discover unique styles at isabel marant outlet.

ile kosztuje kurs na prawo jazdy

Если вы искали где отремонтировать сломаную технику, обратите внимание – профи челябинск

Если вы искали где отремонтировать сломаную технику, обратите внимание – ремонт бытовой техники

Если вы искали где отремонтировать сломаную технику, обратите внимание – сервис центр в барнауле

Если вы искали где отремонтировать сломаную технику, обратите внимание – сервисный центр в барнаул

Если вы искали где отремонтировать сломаную технику, обратите внимание – сервисный центр в челябинске

Если вы искали где отремонтировать сломаную технику, обратите внимание – ремонт бытовой техники в барнауле

The Cruciality of Vibrations Management Apparatus in Machines

In industrial contexts, machines and spinning devices act as the backbone of manufacturing. Yet, one of the commonly prevalent concerns which might hinder the functionality as well as lifetime remains oscillation. Resonance may lead to a series of complications, including lowered perfection and effectiveness resulting in greater wear and tear, eventually leading to high-cost downtime and maintenance. This is when vibration regulation systems becomes essential.

The Reason Vibrations Mitigation is Necessary

Oscillation inside equipment may lead to various harmful effects:

Decreased Functional Performance: Excessive vibrations may cause misalignment as well as distortion, lowering the productivity with the equipment. This may lead to reduced production schedules along with greater energy use.

Elevated Wear and Tear: Constant resonance increases the wear and tear of mechanical parts, resulting in additional servicing along with a risk of unexpected unexpected breakdowns. This not only heightens operational costs but also limits the durability of the existing systems.

Safety Hazards: Unchecked oscillation could pose significant safety risks to the machinery and the equipment along with the personnel. In, extreme situations, such vibrations could bring about catastrophic system collapse, threatening employees and bringing about extensive destruction across the site.

Exactness as well as Quality Concerns: In fields that depend on high accuracy, such as industrial sectors or space industry, oscillations could result in discrepancies in the production process, leading to flawed products as well as more waste.

Reasonably Priced Options for Vibration Regulation

Investing in vibration management tools proves not only essential and also a prudent choice for all businesses that any company dependent on equipment. Our advanced vibration mitigation tools are designed to designed to mitigate vibrations from any mechanical systems as well as spinning equipment, ensuring smooth along with efficient operations.

Something that sets our tools apart is its its affordability. We know the importance of cost-effectiveness in the competitive market of today, which is why we offer high-quality vibration regulation systems at costs that are reasonable.

By choosing these tools, you’re not only securing your mechanical systems along with improving its operational effectiveness as well as putting resources in the enduring achievement of your operations.

Final Thoughts

Resonance mitigation remains a critical element in ensuring the efficiency, security, as well as lifetime of your equipment. Through our cost-effective resonance mitigation apparatus, it is possible to be certain your operations function efficiently, your products remain top-tier, as well as all personnel stay safe. Do not let vibration compromise your operations—put money in the right equipment immediately.

мастер по телевизорам

ремонт телевизора на дому в москве недорого

Если вы искали где отремонтировать сломаную технику, обратите внимание – ремонт техники в челябинске

ремонт телевизора на дому в москве

Если вы искали где отремонтировать сломаную технику, обратите внимание – профи барнаул

Если вы искали где отремонтировать сломаную технику, обратите внимание – ремонт цифровой техники челябинск

The Significance of Vibrations Control Apparatus in Industrial Equipment

In industrial settings, devices along with rotational systems are the core of output. However, one of the most frequent concerns which might obstruct their operation and lifetime exists as vibrations. Vibration can cause an series of complications, from reduced precision as well as productivity leading to elevated deterioration, in the end bringing about pricey delays along with fixes. This is where vibration management equipment is necessary.

Why Vibration Management remains Critical

Oscillation within industrial equipment can lead to multiple adverse impacts:

Lowered Production Efficiency: Exaggerated oscillation might result in misalignment and imbalance, reducing overall productivity in the systems. Such a scenario may cause reduced manufacturing speed along with elevated energy use.

Greater Deterioration: Continuous vibrations hastens overall deterioration of equipment components, leading to more regular repairs along with the risk for unanticipated unexpected issues. This not only raises operational costs and reduces the longevity of your devices.

Safety Concerns: Uncontrolled oscillation might pose substantial safety risks to both the equipment and the machinery and the personnel. In extreme situations, serious conditions, such vibrations could lead to devastating equipment failure, threatening operators and causing considerable devastation to the environment.

Precision and Manufacturing Quality Issues: For industries that require high precision, such as manufacturing and aerospace, vibration might bring about inaccuracies with the manufacturing process, resulting in defects and increased waste.

Affordable Options to Vibration Regulation

Investing in oscillation control equipment remains not merely essential but a sound investment for all businesses that any company involved with mechanical systems. The offered cutting-edge vibration control systems are intended to remove vibrations within all equipment or rotating machinery, ensuring uninterrupted and effective performance.

One thing that differentiates our equipment from others is its affordability. We know the importance of cost-effectiveness in the current market, which is why we provide top-tier vibration control solutions at costs that are affordable.

By choosing our offerings, you’re not only preserving your machines as well as boosting its performance but also putting investment towards the long-term success in your organization.

Final Thoughts

Vibration control is an essential aspect of maintaining the operational performance, safety, and lifespan of your industrial equipment. With these reasonably priced vibration management tools, you can be certain your operations run smoothly, your products are of high quality, as well as all personnel stay safe. Don’t let resonance jeopardize your machinery—invest in the appropriate systems now.

vibration analysis

The Cruciality of Resonance Control Systems in Machinery

Within manufacturing contexts, devices along with spinning systems are the core of production. Yet, a of the commonly frequent challenges that might impede the operation as well as lifetime is vibrations. Vibration might lead to a array of problems, including reduced perfection and productivity to increased erosion, finally leading to pricey downtime and maintenance. This is the point where vibration control tools is vital.

Why Vibration Management proves Critical

Oscillation inside industrial equipment can result in numerous negative consequences:

Minimized Functional Efficiency: Excessive vibration could lead to misalignment along with distortion, minimizing the effectiveness of such equipment. Such a scenario could lead to delayed production schedules and higher energy consumption.

Elevated Deterioration: Constant oscillation accelerates total damage of equipment components, leading to more regular servicing and an risk for unexpected issues. This does not just raises operational costs as well as limits the lifespan in the devices.

Safety Concerns: Uncontrolled vibration could pose significant security risks to both the equipment and the machinery along with the operators. In, serious conditions, these might cause catastrophic system collapse, threatening employees and resulting in considerable destruction to the site.

Exactness along with Production Quality Issues: For businesses which demand high accuracy, for example production or aerospace, vibrations could bring about errors during the manufacturing process, producing defective products along with increased waste.

Reasonably Priced Options for Vibration Management

Investing in oscillation control systems remains not merely essential and also a prudent choice for any organization that relies on mechanical systems. Our advanced vibration control systems are designed to built to eliminate resonance within all equipment and rotational systems, providing uninterrupted and efficient operations.

Something that distinguishes such tools apart is its its reasonable pricing. We understand the significance of keeping costs low in the current market, thus we provide top-tier oscillation control tools at prices that are affordable.

By choosing these tools, you are not just safeguarding your mechanical systems along with enhancing its performance but also investing into the enduring performance of your operations.

Conclusion

Oscillation control is a vital aspect in ensuring the effectiveness, security, as well as lifespan of your equipment. With these reasonably priced vibration control equipment, you can be certain your operations operate seamlessly, all goods maintain top quality, and your workers are protected. Don’t permit vibration jeopardize your company—make an investment in the proper tools today.

Если вы искали где отремонтировать сломаную технику, обратите внимание – сервисный центр в барнаул

сколько стоит ремонт телевизора

Если вы искали где отремонтировать сломаную технику, обратите внимание – выездной ремонт бытовой техники в барнауле

Your passion for this topic is contagious! After reading your blog post, I can’t wait to learn more.

vibration analysis

The Importance of Vibration Management Tools in Machines

Within manufacturing sites, devices and spinning devices are the backbone of operations. Nonetheless, one of the most prevalent challenges which can affect the operation as well as lifetime remains oscillation. Resonance might lead to a array of complications, from decreased exactness along with efficiency leading to elevated damage, eventually resulting in pricey interruptions as well as repairs. This is when resonance control equipment proves to be critical.

Why Vibrations Mitigation proves Necessary

Vibration within machinery can result in numerous detrimental consequences:

Reduced Operational Performance: Excessive vibration might lead to misalignment and imbalance, minimizing the performance with the equipment. Such a scenario may bring about delayed production times and elevated power consumption.

Heightened Erosion: Constant vibration speeds up the wear and tear in machine components, causing additional upkeep and the chance of unexpected unexpected breakdowns. Such a situation does not just elevates operating costs but also limits the lifetime of the machinery.

Security Dangers: Uncontrolled resonance might present major security risks to both the equipment and the equipment along with the operators. In, serious conditions, such vibrations could result in cataclysmic equipment failure, endangering workers as well as resulting in extensive devastation across the environment.

Precision along with Manufacturing Quality Challenges: In fields that demand high precision, including industrial sectors or aerospace, vibrations might result in inaccuracies during manufacturing, resulting in flawed products and increased waste.

Affordable Approaches to Vibration Regulation

Investing in resonance control apparatus is not merely necessary but a sound investment for any organization involved with equipment. Our advanced vibration mitigation tools are designed to mitigate vibrations from various equipment as well as rotating equipment, providing smooth as well as effective performance.

One thing that sets our systems from others is its reasonable pricing. We know the significance of cost-effectiveness inside the modern competitive marketplace, which is why we provide high-quality vibration control solutions at rates that are affordable.

By selecting our offerings, you aren’t simply safeguarding your mechanical systems along with improving its efficiency but also putting investment towards the long-term success of your operations.

Conclusion

Vibration management proves to be a critical aspect in preserving the efficiency, safety, along with durability of your machines. Using our affordable vibration management tools, one can ensure that your operations operate seamlessly, your products remain top-tier, and all personnel stay safe. Do not permit vibration compromise your company—make an investment in the correct apparatus now.

Если вы искали где отремонтировать сломаную технику, обратите внимание – ремонт бытовой техники

мастерская по ремонту телевизоров в москве

Find high-quality fashion at lucky brand store.

ремонт телевизоров в москве недорого

Если вы искали где отремонтировать сломаную технику, обратите внимание – профи барнаул