利用Box2D+WCK賦予Flash物理特性 萬有引力

這已經是第五篇Box2D+WCK的介紹文章了,前面幾篇文章如果各位有注意應該會發現,所有範例的萬有引力都跟現在我們生活的環境一樣,物件像是被地心引力給吸引著都會往下方掉落,其實我們在使用這個模組的時候,也可以改變這樣的萬有引力,讓這些物件不要往下掉落而是往我們所指定的方向移動,馬老師在這邊大概製作了三種不同類型的萬有引力範例,分述如下:

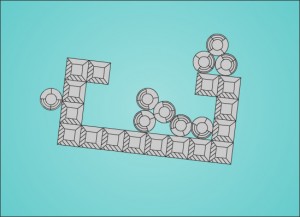

1.容器型萬有引力:這個萬有引力是利用一個封閉的空間來繪製的。

大概的製作步驟如下:

我們可以在World元件中繪製一個如下圖的形狀:

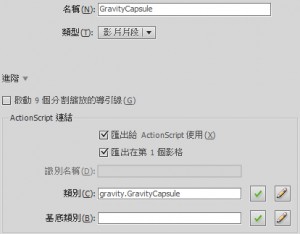

接下來將他轉換成一個影片片段,在類別的部分輸入gravity.GravityCapsule的名稱,如下圖所示:

接下來把這個元件拖曳到World元件裡面就可以了。

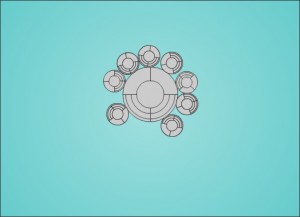

2.放射狀萬有引力:這種萬有引力是以往內或往外放射狀的方式存在。

我們可以在World元件中繪製一個如下圖的形狀:

接下來將他轉換成一個影片片段,在類別的部分輸入gravity.GravityRadial的名稱,如下圖所示:

接下來把這個元件拖曳到World元件裡面就可以了。

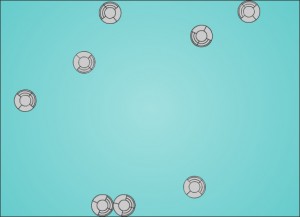

3.正弦萬有引力:就是三角函數的sin。

我們可以在World元件中繪製一個如下圖的形狀:

接下來將他轉換成一個影片片段,在類別的部分輸入gravity.GravitySine的名稱,如下圖所示:

接下來把這個元件拖曳到World元件裡面就可以了。

同樣的也讓大家可以下載以上的三個範例檔,範例檔為CS5格式,下載後要重新設定來源路徑和元件庫路徑喔!希望這個範例對大家有所幫助,如果還有疑問,也可以在這邊回應唷~

glucotrol

online pharmacy in usa: generic lexapro online pharmacy – pharmacy online tadalafil

Профессиональный сервисный центр по ремонту варочных панелей и индукционных плит.

Мы предлагаем: варочная панель ремонт

Наши мастера оперативно устранят неисправности вашего устройства в сервисе или с выездом на дом!

Профессиональный сервисный центр по ремонту бытовой техники с выездом на дом.

Мы предлагаем:ремонт бытовой техники в екб

Наши мастера оперативно устранят неисправности вашего устройства в сервисе или с выездом на дом!

https://pharm24on.com/# clozaril pharmacy registration

fluoxetine india pharmacy

Upgrade your wardrobe with the latest from agolde jeans.

ремонт мыльниц

prawo jazdy c

Find unique pieces at namilia outlet.

Если вы искали где отремонтировать сломаную технику, обратите внимание – ремонт бытовой техники

Если вы искали где отремонтировать сломаную технику, обратите внимание – ремонт бытовой техники в челябинске

Если вы искали где отремонтировать сломаную технику, обратите внимание – ремонт бытовой техники в челябинске

Если вы искали где отремонтировать сломаную технику, обратите внимание – ремонт бытовой техники

Если вы искали где отремонтировать сломаную технику, обратите внимание – профи тех сервис челябинск

Если вы искали где отремонтировать сломаную технику, обратите внимание – профи ремонт

Если вы искали где отремонтировать сломаную технику, обратите внимание – ремонт бытовой техники

The Value of Resonance Management Equipment in Industrial Equipment

In production contexts, devices and turning devices act as the foundation of manufacturing. However, a of the most prevalent challenges which might affect the functionality and lifespan is resonance. Vibration can bring about a range of issues, from lowered exactness as well as productivity leading to elevated erosion, finally resulting in pricey downtime as well as repairs. Such a situation is when vibration regulation systems proves to be essential.

The Reason Vibration Control is Important

Vibration inside industrial equipment can result in various harmful impacts:

Lowered Operational Productivity: Excessive resonance might result in misalignment and imbalance, reducing total effectiveness in the devices. Such a scenario can lead to slower production schedules along with increased power consumption.

Elevated Damage: Constant vibration hastens the damage in machine components, causing more regular servicing and a risk for unforeseen malfunctions. Such a scenario not only heightens operating costs and reduces the lifetime of the existing devices.

Security Hazards: Unmanaged resonance could pose substantial safety concerns for both the equipment and the machinery and the workers. In, serious conditions, it can bring about devastating equipment failure, jeopardizing operators and leading to widespread damage to the environment.

Precision as well as Quality Challenges: For sectors that require precise production, for example production or aviation, resonance might bring about discrepancies in the manufacturing process, producing flawed products as well as increased waste.

Reasonably Priced Alternatives to Vibration Management

Investing in oscillation control apparatus proves not just essential and also a prudent choice for any organization involved with equipment. The offered state-of-the-art vibration regulation equipment are built to mitigate vibrations from various mechanical systems or rotating equipment, guaranteeing smooth as well as efficient operations.

What sets such systems apart is its its economic value. We understand the importance of keeping costs low inside today’s competitive market, which is why our offerings include premium vibration control solutions at pricing that are reasonable.

Through selecting our equipment, you aren’t simply preserving your mechanical systems as well as boosting its efficiency you’re also investing in the long-term achievement of your business.

In Conclusion

Vibration control is a vital element of maintaining the operational performance, safety, along with longevity of your equipment. Using our affordable vibration management tools, one can ensure that your production function efficiently, your products are of high quality, along with your employees are protected. Don’t let vibration undermine your business—invest in the correct apparatus today.

ремонт телевизоров в москве недорого

сколько стоит ремонт телевизора плазма

ремонт матрицы телевизора

vibration analysis

The Significance of Resonance Management Equipment in Industrial Equipment

In industrial settings, machines and spinning systems constitute the backbone of production. Yet, an of the commonly common problems that may hinder the performance as well as lifespan exists as resonance. Vibration could result in an variety of problems, such as decreased perfection and productivity to heightened erosion, finally resulting in costly downtime and fixes. This is when resonance control tools proves to be vital.

Why Vibration Management is Necessary

Oscillation within machinery can bring about several adverse impacts:

Minimized Operational Performance: Excess vibration can lead to discrepancies and instability, decreasing the efficiency of the devices. This might cause slower output times and increased energy consumption.

Heightened Wear and Tear: Constant resonance speeds up the deterioration to machinery parts, resulting in increased upkeep and the potential for unexpected failures. Such a scenario does not just raises operational costs but also decreases the lifetime of the systems.

Protection Risks: Unmanaged vibrations might pose substantial safety risks to both the machinery as well as the operators. In, severe cases, it can lead to cataclysmic system collapse, endangering employees and leading to considerable harm to the environment.

Precision and Quality Concerns: Within fields that depend on precise production, such as manufacturing and aviation, oscillations could cause errors in the manufacturing process, causing faulty goods and increased waste.

Reasonably Priced Approaches for Vibration Management

Investing in vibration management apparatus proves not merely a necessity but a smart decision for all businesses that any business that uses machinery. Our cutting-edge vibration regulation equipment work to designed to reduce vibrations from any equipment and rotating equipment, providing smooth along with effective performance.

What differentiates such systems apart is its reasonable pricing. We understand the necessity of cost-effectiveness in today’s competitive market, and for that reason we offer high-quality oscillation control tools at costs that remain budget-friendly.

By choosing our systems, you’re not only protecting your machinery and improving its operational effectiveness you’re also investing towards the sustained success of your business.

Final Thoughts

Oscillation control proves to be a vital factor in ensuring the efficiency, security, along with lifespan of your machinery. With these reasonably priced resonance mitigation apparatus, you can make sure your processes operate seamlessly, your products are of high quality, and your workers remain safe. Do not allow resonance undermine your business—invest in the right equipment today.

ремонт телевизоров в москве ремонт тв

Hello friends, fastidious piece of writing and nice arguments commented here, I am genuinely enjoying by these.

Midlife It

The Significance of Oscillation Regulation Systems in Machinery

Across production environments, machinery and rotating equipment serve as the backbone of operations. Nonetheless, an of the most prevalent concerns that may impede their efficiency and lifetime remains vibrations. Oscillation can lead to an range of issues, from minimized precision and performance resulting in elevated erosion, finally leading to pricey downtime and repairs. This scenario is when vibration regulation equipment proves to be necessary.

The Reason Vibration Management is Crucial

Vibration in industrial equipment might lead to multiple adverse consequences:

Decreased Functional Effectiveness: Excess vibrations might cause misalignment and imbalance, minimizing the performance in the devices. Such might cause slower manufacturing speed as well as elevated electricity usage.

Elevated Erosion: Persistent vibration accelerates the damage in machine components, bringing about more frequent servicing and the risk for unexpected breakdowns. Such a situation doesn’t merely raises operating costs and decreases the lifespan of the equipment.

Safety Risks: Unchecked resonance can present substantial safety risks both to the machinery and the machinery along with the operators. In extreme situations, severe cases, this may cause disastrous equipment breakdown, threatening operators and causing widespread devastation to the premises.

Precision along with Manufacturing Quality Concerns: In businesses that depend on high accuracy, such as production or space industry, oscillations can cause inaccuracies in the manufacturing process, causing flawed products and increased waste.

Cost-effective Approaches for Oscillation Control

Investing in vibration control equipment remains not just essential but a prudent choice for any business any industry involved with equipment. Our modern vibration regulation equipment work to built to remove vibrations from any equipment as well as rotating machinery, ensuring seamless and efficient functioning.

One thing that sets these tools above the rest is its economic value. It is recognized that the significance of cost-effectiveness inside the modern competitive marketplace, thus we have premium vibration control solutions at prices that won’t break the bank.

Opting for our equipment, you’re not only safeguarding your machines and enhancing its operational effectiveness but also putting resources in the enduring success in your organization.

Conclusion

Vibration management is an essential element in ensuring the efficiency, protection, as well as lifetime of your machinery. Through these reasonably priced oscillation control systems, it is possible to ensure that your processes run smoothly, all manufactured items remain top-tier, along with all personnel stay secure. Do not let oscillation affect your operations—invest in the right equipment immediately.

Если вы искали где отремонтировать сломаную технику, обратите внимание – выездной ремонт бытовой техники в челябинске

Если вы искали где отремонтировать сломаную технику, обратите внимание – техпрофи

Если вы искали где отремонтировать сломаную технику, обратите внимание – ремонт техники в челябинске

Если вы искали где отремонтировать сломаную технику, обратите внимание – ремонт бытовой техники

Upgrade your wardrobe with elegant pieces from pistola jeans sale.

Если вы искали где отремонтировать сломаную технику, обратите внимание – ремонт бытовой техники